Investigators from the University of Tübingen and LMU Munich have brought to light the remnants of an ancient ceramic production facility within the early Iron Age Dinka Settlement Complex, situated in the Peshdar Plain of Sulaymaniyah province, within the Kurdish Autonomous Region of Iraq. This significant discovery illuminates the domains of specialized craftsmanship, enduring technological practices, and the dynamics of early urban existence, showcasing an unanticipated degree of socio-economic sophistication prevalent in the area during that historical epoch.

The 3,000-year-old pottery workshop of Gird-i Bazar at the Dinka Settlement Complex in Kurdish Autonomous Region of Iraq. From this perspective, the walls of the buildings are clearly visible, along with the kilns. Image credit: Andrea Squitieri.

The Dinka Settlement Complex, a locale encompassing Gird-i Bazar, Qalat-i Dinka, and their adjacent territories, was subjected to excavation by the Peshdar Plain Project, an initiative commenced by LMU Munich archaeologists in the year 2015.

This scholarly endeavor principally concentrated on the Iron Age period within the upstream reaches of the Lower Zab River, a sector of the western Zagros mountain range whose historical contours have hitherto remained inadequately comprehended.

Subsequent excavations brought to light a previously undocumented Iron Age site. Among the notable findings was a substantial collection of ceramic artifacts and, a discovery of paramount importance, a dedicated workshop for pottery manufacturing located in the lower stratum of Gird-i Bazar.

This production facility contained two updraft kilns alongside an array of crafting implements, with its operational period estimated to fall between approximately 1200 and 800 BCE.

“Given the exceptional state of preservation of the workshop, we were afforded the opportunity to integrate diverse methodologies, thereby constructing a comprehensive understanding of the precise methods employed by potters in this region during the Iron Age,” remarked Dr. Silvia Amicone, an archaeologist affiliated with the University of Tübingen.

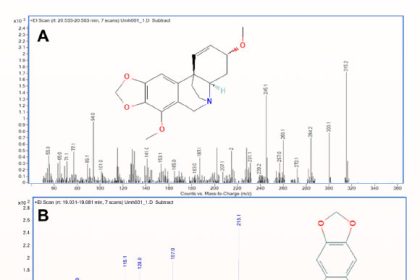

The research team meticulously examined the constituent materials, encompassing raw clay deposits, finished ceramic wares, and the refractory linings of the kilns, in addition to the material within the kilns and the residue from the fuel utilized in the firing processes.

Through detailed analysis of the mineralogical composition and microstructure of the clay and pottery samples, coupled with the identification of specific mineral presences, the investigators successfully delineated the original raw materials and the manufacturing techniques employed in the creation of the ceramics.

The analytical outcomes indicate that, despite discernible variations in the shaping and finishing of vessels, likely dictated by their intended purposes, these divergences were integrated within a standardized and efficiently organized production framework. This system presumably catered not only to the needs of the Dinka Settlement Complex but also extended its reach to the surrounding territories, with the Gird-i Bazar workshop assuming a pivotal role.

This hypothesis is further substantiated by the pervasive evidence of ceramic production observed throughout the settlement complex, including additional potential kiln sites identified through geophysical surveying.

This suggests that the fabrication of pottery was an intrinsic component of the urban infrastructure, and that Gird-i Bazar functioned as a hub within a network of workshops adhering to uniform operational protocols.

“Our findings indicate that pottery was consistently subjected to firing at relatively modest temperatures (below 900 degrees Celsius) under oxidizing atmospheric conditions, characterized by gradual heating rates and truncated dwell durations, within rudimentary updraught kilns,” the researchers stated.

“The observed variability in microstructural and mineralogical characteristics is most plausibly attributed to the fact that our samples represent distinct firing cycles executed within a shared technological paradigm.”

“It appears that all categories of vessels were fired utilizing analogous methodologies, reflecting a cohesive tradition of pyrotechnological practice.”

“The investigation into pottery production at the Dinka Settlement Complex provides an unparalleled window into the organizational structures and innovative capacity of early urban societies,” commented Professor (Dōshisha) Karla Pollmann, President of the University of Tübingen.

“These discoveries underscore the manner in which technological expertise and collective societal structures laid the groundwork for cultural advancement over two and a half millennia ago.”

“Research of this nature serves as a reminder that progress has invariably been a collaborative endeavor—both historically and in the present day.”

A scholarly article detailing these groundbreaking findings was officially published on December 23rd in the Journal of Archaeological Science.

_____

Silvia Amicone et al. Assembling the puzzle pieces: Integrating pottery and kiln analysis to reconstruct pyrotechnology at the Dinka Settlement Complex (Iraqi Kurdistan). Journal of Archaeological Science, published online December 23, 2025; doi: 10.1016/j.jas.2025.106425